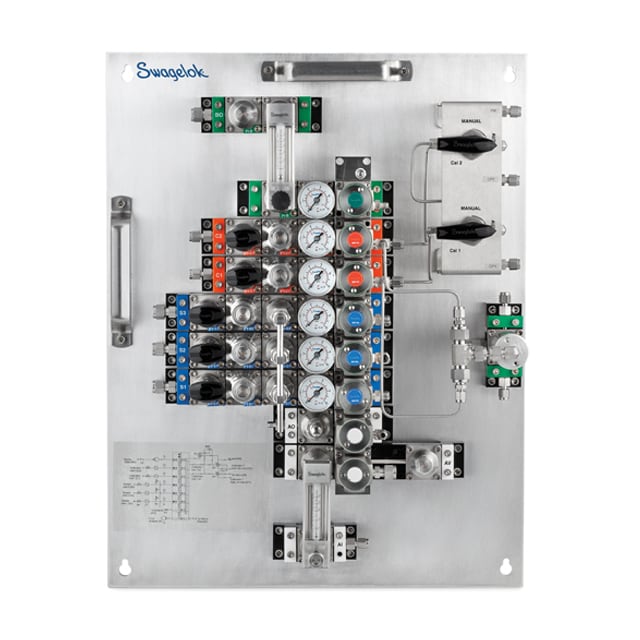

Field Station Module (FSM)

Field Station Module (FSM)

A Swagelok field station module (FSM) reduces process gas pressure before transporting it to an analyzer. Transporting a gas sample at low pressure offers three major benefits:

• Faster analyzer response time

• Less condensation

• Safer environment

Faster Analyzer Response:

In a high-pressure line with downstream flow control, gas molecules are more densely populated which creates slower flow velocity and longer purge times. Lowering the pressure of a gas sample means fewer molecules in the sample transport line and sample conditioning components; therefore, it is easier to flush the system, and the analyzer can respond faster to process changes.

The amount of gas held in the transport line is proportional to its absolute pressure. At half the absolute pressure, there are half as many gas molecules in the line, so—all other things being equal—it takes half the time for a fresh sample to reach the analyzer.

Typically, an FSM is used when process pressure is 3 bar (gauge) (43.5 psig) or higher.

Less Condensation:

The relative humidity of a gas is directly proportional to the partial pressure of water vapor in the mixture. A relative humidity (or saturation) of 100 % represents the maximum partial pressure of water vapor possible at a working temperature. Therefore, if water vapor in any gas mixture reaches 100 % of its saturation limit, water vapor will begin to condense in a sample transport line. To avoid condensation in gas sampling, the FSM reduces the partial pressure of every gas in the sample mixture. One way to lower partial pressure of every gas is to reduce overall system pressure; the partial pressure of each gas drops in proportion to the overall pressure change.

For example, if the absolute pressure of a sample is cut in half, the partial pressure of each gas

in the mixture is cut in half as well, which results in half the water saturation in the sample. Using an FSM significantly reduces the chance of condensation forming in the sample transport line.

Safer Environment:

If a system is compromised, the pressurized gas will expand to atmospheric pressure rapidly and can cause system damage or personal injury. The volumetric expansion ratio is directly proportional to the absolute pressure decrease. In high-pressure systems without field station modules, the expansion can be so great that the result is explosive in nature. Installing an FSM at the process sampling point means a smaller section of the sample system is exposed to high pressure, resulting in a safer overall environment.