: Consideration for Hose Insulation

Consideration for Hose Insulation

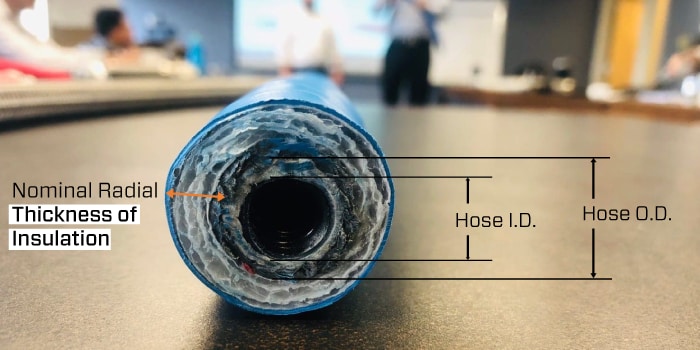

Hose insulation help keep system fluid inside the hose at desired temperature levels, especially important when maintaining hot or cold fluid temperature are required. Before selecting insulated hose, there are couple thing you should consider.

1: Free Air Convection

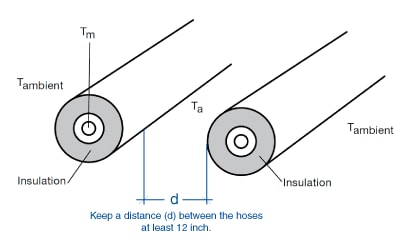

Hoses that transfer cold or hot fluids can impact the temperature of other nearby fluid systems.

When cold hoses are routed too close to each other, the surface temperature of the hoses can fall below the dew point, causing condensation to form. When hot hoses are routed too close to each other, hot spots can develop that are above allowable temperature parameters.

The smaller the distance (d) between the hoses, the closer the air temperature (Tambient) between the hoses will be to the media temperature (Tm) in the hose. A general recommendation is to keep hoses at least 12 in. (31 cm) apart. If hoses are spaced closer than this, consider using additional layers of insulation.

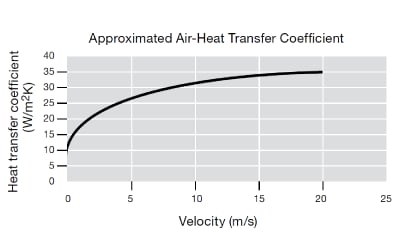

2: Air Flow

Stagnant air creates an undesirable scenario for the surface temperature of the hose due to the decrease in heat transfer coefficient. As air flow increases, surface temperatures will trend more towards the ambient environment temperature.

One worst-case example is when a hose is routed through a confined area, such as a subfloor. In the case of cold media flowing through the hose, this could cause condensation to form on the outside of the hose which may drip onto sensitive electronics.

3: Humidity and Dew Point

Dew point can be approximated using the formula:

Td = T – [(100 - RH)/5]

where

Td is the dew point temperature (in degrees Celsius),

T is the ambient air temperature (in degrees Celsius), and

RH is the relative humidity (in percent).

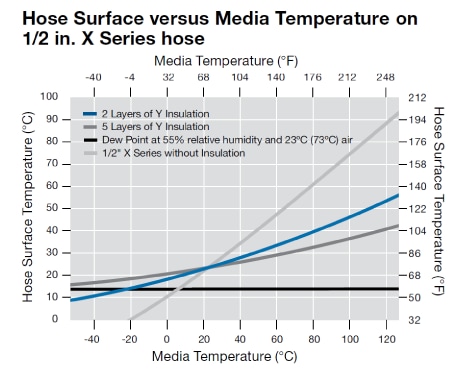

When selecting the number of layers of insulation to prevent condensation in an application, use the highest expected humidity that the hose will experience.

4: Energy Savings

Uninsulated hoses are a constant source of wasted energy. Insulation can typically reduce energy losses by up to 90% and help ensure proper and consistent temperature of plant equipment.

Other reasons to insulate these hoses include:

■ To facilitate proper temperature control to a process, such as steam or coolant lines.

■ To protect the environment and reduce the amount of energy used for heating purposes, resulting in lower emissions.

■ To control surface temperatures for personnel protection and safety.

5: Safe-To-Touch Recommendations

ASTM C1055 (Standard Guide for Heated System Surface Conditions that Produce Contact Burn Injuries) recommends that surface temperatures remain at or below 60°C (140°F), as the average person can touch a 60°C (140°F) surface for up to five seconds without sustaining irreversible burn damage. Choosing the proper thickness of insulation can lower the external temperature to reduce the chance of a burn injury.

6: Bending an Insulated Hose

Hose technical data, including minimum bend radius, does not change when insulating a hose.

However, bending the hose may affect the insulation properties, as shown in Figure.

To minimize these effects, employ bends with a larger bend radius.

If this is not possible, consider using additional layers of insulation.

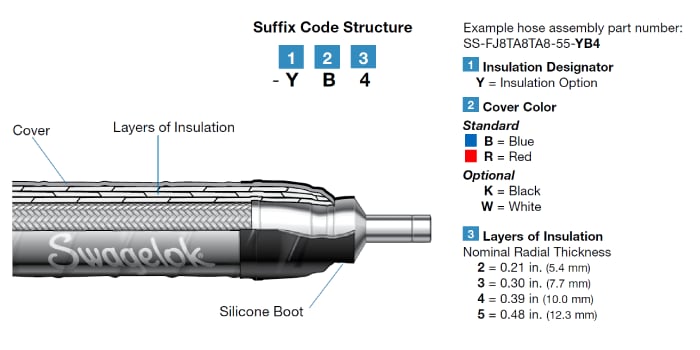

How to select Swagelok insulated option?

Swagelok Y-Insulated Hose Option

■ Rated for continuous hose surface temperature use from

-53°C up to 125°C

■ Low thermal conductivity aerogel insulation material

minimizes the bulk needed to achieve desired surface

temperatures

■ Flexible polyolefin heat shrink cover enables the product

to be flexible, vapor permeation resistant, and abrasion

resistant

■ Silicone boots at hose ends protect the insulation

Test conditions for example plots:

■ Environment temperature: 23°C (73°F)

■ Air flow: Isolated in a chamber with no air flow

■ Media Pressure: 6 to 10 psi (0.41 to 0.68 bar)

■ Media Flow Rate: 22 to 26 l/min

■ Media type: Liquid

■ Free air around hose: 6 in (15.2 cm)

For more information about Swagelok insulated hose, contact to Swagelok Thailand

Find More About Hoses Product

Four Steps to Safer Hoses

Four simple ways designers keep plants running and minimize potentially dangerous situations involving hoses.

Swagelok® Hose Advisory Services

Eliminate a variety of hose-related issues that cause safety concerns, unplanned downtime, low product yield, or costly part replacements by engaging Swagelok® hose advisory services.