Material Selection Guide

An offshore platform can have nearly 50,000 feet of tubing, more than 20,000 fluid system components, no fewer than 10,000 fittings, and as many as 8,000 mechanical connections.

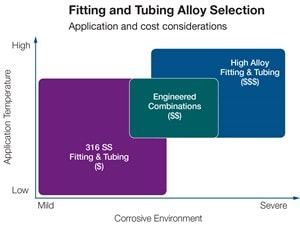

No wonder choosing one material isn’t easy. In fact, there are many considerations when specifying materials for instrumentation lines, hydraulic power, chemical injection, deluge systems, and much more.

That’s where Swagelok can help. We’ve been fighting corrosion since 1947. We simplify selection with our deep understanding of factors that contribute to corrosion, as well as the properties of materials that help fight it. We use alloys with at least two, but often up to ten different elements in optimized concentrations which give our materials superior corrosion resistance that helps our products perform better.

For instance:

Nickel [Ni] + Copper [Cu] = Alloy 400 (Monel®)

Iron [Fe] + Nickel [Ni] + Chromium [Cr] + Molybdenum [Mo] = 316 Austenitic Stainless Steel

With stringent quality control measures, expert-led instruction, and authorized sales and service center support, Swagelok offers unmatched expertise in the world’s toughest environments. We make material selection a matter of confidence for our customers.

> View and download a print-friendly version of the Materials Selection Guide

An offshore platform can have nearly 50,000 feet of tubing, more than 20,000 fluid system components, no fewer than 10,000 fittings, and as many as 8,000 mechanical connections.

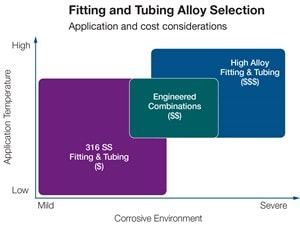

No wonder choosing one material isn’t easy. In fact, there are many considerations when specifying materials for instrumentation lines, hydraulic power, chemical injection, deluge systems, and much more.

That’s where Swagelok can help. We’ve been fighting corrosion since 1947. We simplify selection with our deep understanding of factors that contribute to corrosion, as well as the properties of materials that help fight it. We use alloys with at least two, but often up to ten different elements in optimized concentrations which give our materials superior corrosion resistance that helps our products perform better.

For instance:

Nickel [Ni] + Copper [Cu] = Alloy 400 (Monel®)

Iron [Fe] + Nickel [Ni] + Chromium [Cr] + Molybdenum [Mo] = 316 Austenitic Stainless Steel

With stringent quality control measures, expert-led instruction, and authorized sales and service center support, Swagelok offers unmatched expertise in the world’s toughest environments. We make material selection a matter of confidence for our customers.

> View and download a print-friendly version of the Materials Selection Guide