Onsite Supervision Services

Onsite Supervision Services

Bad installation always comes with big problem, start the first button right with Swagelok Onsite Supervision Services.

Are you facing some problem as below at your plant?

Example below shown some of the most installation errors commonly found during onsite inspection. Swagelok Thailand, we provide fluid system installation supervision services to help prevent errors throughout construction or expansion project. This will minimize the need for rework during hookup and commissioning, as well as costly maintenance and repair once your asset is in service.

Improper Installation

Error installation due to skill labor —

Tube not bottomed and non-deburred tube that might cause fluid system failure

Poor maintenance root line

Tubing installation without expansion loop will limit access during maintenance

What Swagelok Thailand do to support you?

Onsite supervision service help EPCs and contractors reduce the cost and time required for proper fluid system installation. Ensure onsite activities adhere to Small Bore Tubing (SBT) installation which can increase plant safety and reliability of fluid system for operators.

Swagelok Technical Support Engineer can help address concerns related to cost, quality, and time by providing:

: Check all necessary tools and equipment need to ensure the contractor can complete their job with proper installation

: Onsite guidance, training and discussing a scope of work with contractor to get the job done on plan

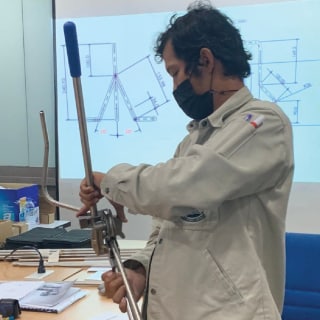

: Apply special equipment during installation to ensure an accuracy and quality of installation meet Small Bore Tubing (SBT) installation best practice for example depth making tools and hydraulic pre-swaging unit

: Design consultant for layouts and components - we can assist in designing fluid systems that reduce wear and extend component life by accounting for factors like temperature, pressure, and potential vibration. Or event advise on an installation expansion loops in a system offer easier access for regular maintenance and repair

: Quality check of fluid system installation during construction, our Technical Support Engineer will check all connection to ensure system safety and integrity

How this services benefit to you?

Onsite supervision is a service that can help prevent errors during construction and expansion projects. This can reduce the need for rework during commissioning and hookup. Moreover, its aims to assist the operator on identifying the major elements required to build an effective small bore tubing assemblies during an installation process or construction.