: Push The Limit of ALD Technology

Push the Limits of ALD Technology

High flow. High temperature. High performance.

The next generation of semiconductor manufacturing starts here.

Today's cutting-edge semiconductor chip production processes demand materials and product designs that not only stand up to corrosive gases and extreme temperatures, but also provide precise dosing over tens of millions of cycles.

Speed, repeatability, and cleanliness are essential.

And it is not only the demands of today that matter. Forward-looking companies also need products that allow them to employ the low-vapor pressure chemistries and processes necessary to maintain a competitive edge in a quickly evolving technology market.

Substantial opportunity for improved efficiency, consistency, and innovation exists within the semiconductor chip manufacturing market. That is why Swagelok—the originator of atomic layer deposition (ALD) valve technology—has developed the ALD20 ultrahigh-purity (UHP) valve to provide semiconductor industry leaders with the precision and performance they need for next-generation ALD process applications.

Enabling what's next.

The patent-pending ALD20 valve design provides the reliability and performance that customers have come to expect of Swagelok ultrahigh-purity ALD valves while opening up opportunities to work with precursor gas chemistries that were previously challenging. The high flow capacity and thermal stability supported by ALD20 valves make it possible to consistently maintain the high temperatures and minimized pressure drop necessary to quickly deliver a broader range of compounds in a compact footprint.

As a result, semiconductor chip manufacturers adopting the ALD20 can now utilize more low-vapor pressure precursors, achieving the uniform deposition needed to develop today’s most advanced technology and discovering competitive advantages for tomorrow.

Improved flow. Minimized footprint.

The new ALD20 UHP valve is specifically designed to extend the limits of ALD valve technology, enabling flow rates two to three times what can be achieved using today's standard ALD valve. These higher flow rates result in very low pressure drop across the valve, making low-vapor pressure precursor chemistry options more practical. In some applications, the ALD20 valve will allow manufacturers to take advantage of elevated flow rates to maximize process efficiency.

• The ALD20's compact 1.5-in. modular-surface mount footprint can deliver a flow rate of 1.2 Cv without requiring retooling of existing equipment or additional process changes.

• A standard body style ALD20 valve with a slightly larger footprint width (1.75 in.) can yield a flow rate of 1.7 Cv.

• Custom set flow coefficients are also available.

Uncompromising consistency.

The ALD20 offers ease-of-use improvements for ALD processes too. The valve and actuator can be fully immersed in a gas box up to 392ºF (200ºC). This enhanced thermal stability within process lines ensures low-vapor pressure gases are kept at temperatures conducive to optimal flow, allowing for consistent, high-quality deposition.

Other ALD20 features promote long-lasting, consistent operation as well.

• 316L VIM-VAR stainless steel or Alloy 22 body materials provide enhanced corrosion resistance to withstand increasingly aggressive media.

• A highly polished bellows with a 5 μin. Ra finish promotes clean operation over an ultrahigh cycle life for process integrity.

• A pneumatic actuator can deliver high-speed (<10 ms), repeatable actuation for precise, consistent flow to meet dosing requirements.

Unbeatable quality. Designed to fit.

The ALD20 valve is the latest example of Swagelok's commitment to quality, innovation, and continuous improvement, as well as the company’s commitment to designing products that relieve its customers’ greatest business pressures. It is available today in modular surface-mount configurations with two or three ports, in straight configurations with tube butt weld and male or female VCR® face seal fitting end connections, and in multiport valve configurations to optimize flow paths within existing or new systems. A high-temperature optical position sensor is available as an add-on component.

For years, semiconductor manufacturers have seen optimization of atomic layer deposition (ALD) processes as critical to the success of their businesses. Essential to these processes are ultrahigh-purity (UHP) valves that are highly engineered to deliver precise doses of gases during the deposition process used to create semiconductor chips. While relatively small components, these valves have a huge impact on the success or failure of the chip-building process.

UHP valves used in ALD processes are quite advanced compared to valves commonly found in general industrial applications, yet semiconductor manufacturers have still found themselves seeking higher performance when it comes to factors like thermal stability and flow capacity of late. The capabilities of ALD valves have not changed drastically in many years, yet it is apparent that change is needed if the semiconductor industry is to reach new levels of innovation and productivity.

Recognizing Room for Improvement

Thermal Stability

UHP valves must be heated to high temperatures during the ALD process to keep low-vapor pressure gases from solidifying prematurely. The actuators on existing UHP diaphragm valves often cannot be completely immersed in the gas box, however, and must be thermally isolated to maintain their functionality. This can cause a discrepancy in temperature between different components of the valve. When this occurs, cooling of transmitted gases can occur, as seen in Figure 1, with different colors representing varying temperatures.

This is especially problematic when using precursors that require precise temperature stability to remain in a gaseous state prior to deposition, resulting in unwanted residue buildup leading to inconsistent dosing. Given the importance of repeatability in the semiconductor market, the elimination of any potential for variance or inconsistency would be welcomed by many.

Flow Rate

Another key challenge for semiconductor tool OEMs and fabricators is the limited flow capacity of existing UHP valves suitable for ALD processes. While existing UHP diaphragm valves offer flow rates that have generally been acceptable up to now, those rates can decline as the valve is heated. Boosting flow rate capabilities of valves could boost the rate at which fabricators can produce semiconductor wafers—or at least could allow them more process flexibility to ensure the stability of their precursor gases—potentially boosting revenues in the process.

Ability to Experiment

Ability to Experiment

While there are plenty of challenges inherent to semiconductor manufacturing today, there is also a need to experiment with new processes and media that can enable competitive advantage tomorrow.

There is potential for fabricators to improve upon today’s microchip technology and ALD processes by using new highly reactive precursor gases, but existing ALD valve technology does not currently provide the consistently high flow rate necessary to avoid pressure drop across the valve, which can cause low-vapor pressure gases to change states. Figure 2 illustrates how flow rate can impact pressure drop in three different valves.

Fabricators can slow the flow rate in their process enough to achieve the low pressure drop required to use these low-vapor pressure precursor gases but doing so is generally not economically viable due to the required drop in overall system efficiency. Improvements in UHP valve technology will be the key to helping semiconductor manufacturers discover what’s next without sacrificing financial sustainability.

Three Challenges, One Solution

The good news is the next generation of ALD valves is hitting the market, and their design improvements over existing ALD valve technology hold great promise for the future of microchip manufacturing. Here are three reasons for a positive outlook.

1. The valves are totally immersible in the gas box.

1. The valves are totally immersible in the gas box.

In an application where consistency is key, there is now less risk of buildup or deposition inconsistencies compared to today’s ALD processes. The design of new ALD valves allows for the entire valve to be heated up to 200°C (392°F), as the actuator does not need to be isolated to maintain its integrity or dosing precision. This means that semiconductor fabricators can feel confident that the gases flowing through next-generation ALD valves will be exposed to a uniform temperature, taking some degree of variability out of the process. Figure 3 shows an ideal state of thermal stability, as compared to Figure 1 with its varied temperatures.

2. The flow rates can be much higher.

Semiconductor industry leaders can now achieve the greater flow rates they’ve sought without having to compromise on cleanliness or component longevity. Whereas existing valves might offer a 0.6 Cv flow coefficient, new valves can offer double the flow (1.2 Cv) in the same footprint (1.5 in.), allowing for tool manufacturers to provide greater output without requiring retooling or other significant process changes. If, however, a fabricator has the flexibility to implement new ALD valves with a slightly larger footprint (1.75 in.), they can nearly triple the flow rate of existing ALD valves, achieving flow coefficients of up to 1.7 Cv.

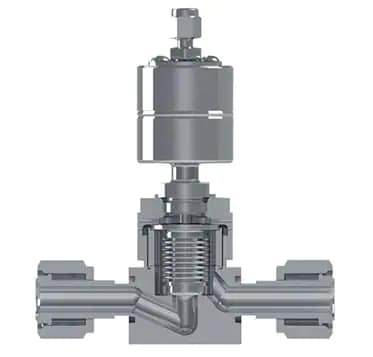

These substantial improvements in flow capacity are made possible by new ALD valves featuring a bellows design rather than a traditional diaphragm design. Bellows valves are capable of higher flow rates, and the bellows inside new ALD valves are highly polished to a 5 μin Ra finish to achieve the UHP performance manufacturers have come to expect from diaphragm valves currently used in the market. In Figure 4, you can see the bellows featured in the center of the valve. The new design combines the best features of both valve technologies into one UHP valve with an ultrahigh cycle life.

3. Improved performance attributes allow for innovation.

3. Improved performance attributes allow for innovation.

Forward-thinking players in the semiconductor industry will now be less constrained from an innovation perspective. New ALD valve technology provides the performance and durability to allow semiconductor manufacturers to work in new areas of the periodic table of elements, experimenting with low-vapor pressure precursor gases to find materials that might perform better than what is used in ALD processes today. Beyond maintaining consistent temperature and allowing for higher flow rates, new ALD valves are being offered in highly corrosion-resistant materials such as Alloy 22, meaning more aggressive chemistries can be used for processing without concern about problematic pitting or crevice corrosion.