: AGI Packaged Pump Systems

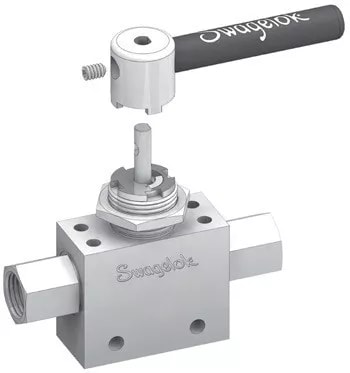

Shutoff off Subsea Wellheads With Integrators for Medium Pressure Ball–Valves

|

|

As a leading provider of packaged pump systems for the oil and gas industry, AGI Industries cannot endure setbacks caused by leaks or failure from its component parts. So when the company sought out a fitting and valve solution that could withstand 15,000 psi for the demanding needs of its chemical injection skids, they turned to Swagelok® |

The ChallengeAGI Industries's chemical injection skid systems require uncompromising, leak-free performance at 15,000 psi. Fixing valve and fitting issues can take dozens of hours in manpower and weeks of downtime. |

The SolutionSwagelok FK series valves and fittings with patented technology provide: • Easier installation

• A superior seal

• Greater tube compatibility

• Leak-free performance

|

The ResultAfter installing FK series valves and fittings on nine chemical injection skids with 13,500 potential leak points, AGI Industries: 1. Detected 0 leaks over 6,000 cycles

2. Saved over 160 man-hours

3. Realized up to 100x more valve cycles

|

|

AGI Industries

Each of AGI's chemical injection skids requires up to 1,500 individual connections — meaning 1,500 potential leak points. Once the skid is in operation, finding and fixing leaks require significant labor resources and can put production 12 to 14 weeks behind schedule.

Swagelok helped AGI identify a solution to meet the challenge: FKB series valves and FK series fittings. Featuring patented compression fitting technology, Swagelok’s solution is easier to install, offers a superior seal, and is compatible with a wider variety of tubing types when compared to common cone and thread technology. The FKB series valve handled 6,000 cycles of hydrotesting with no leaks, while other comparable ball valves leaked at 60 to 120 cycles.

“Swagelok has always been the one who listens,” said Tony Taylor, AGI Industries design systems analyst. “They work harder. There have been no problems at all with Swagelok, even with thousands of connections.”

AGI installed FK series products on nine skids. With 13,500 connections, zero leaks were recorded. FK series performance greatly reduced the risk of errors of traditional cone and thread valves, helping AGI save significant time and money.

|

|

This illustrates the addition of a stop plate to the handle design of the FKB series ball valve. The stop plate may be repositioned, shifting the on and off position by 90-degree increments. |

FK Series Medium Pressure Fittings

New fittings technologies offer leak-tight connections for topsides fluid system applications

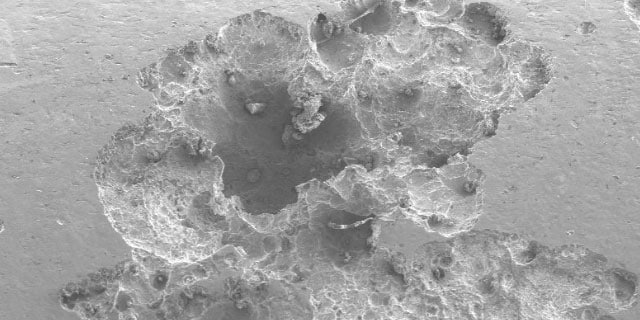

Material Corrosion

Corrosion—the deterioration of engineering materials, most commonly metals, by chemical interaction with their environment—is an extraordinarily costly problem.

Oil and Gas

Find the high-quality fluid system products and deep understanding of oil and gas applications you need to improve the safety and productivity of fluid system operating in challenging environments