Assembly-by-Torque (AbT) Fittings

Assembly-by-Torque AbT Fitting

Offering reliable and repeatable assembly methods, the assembly-by-torque (AbT) fitting assembles quickly. Assembly to a pre-determined torque facilitates reliability and repeatability of fitting assemblies. In tight spaces, the AbT fitting can be assembled by hand, with no special tools required. For difficult-to-reach or confined space applications, preswaging prior to assembly eases installation and speeds up production.

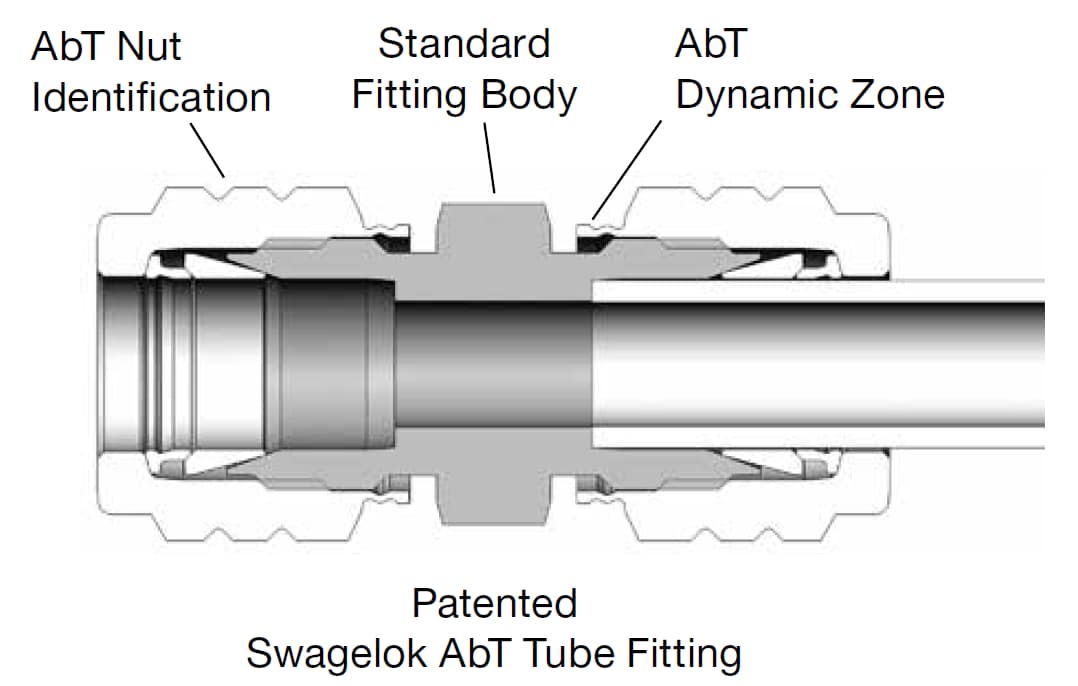

Swagelok AbT fittings utilize a unique stop feature, known as a dynamic zone (patented), integrated into the highly-reliable, widely used, Swagelok tube fitting. In all sizes, the design controls axial displacement of the nut during assembly and disassembly.

AbT fittings feature a patented dynamic zone feature on the nut which provides a prescribed resistance, at a predetermined position, during the assembly-by-torque installation pull-up. These unique nut and ferrule sets can be assembled to standard Swagelok tube fitting bodies to create an assembly-by-torque tube fitting.

Features

■ Assembly by torque.

■ Sizes: 1/4 in., 3/8 in., 1/2 in., 6 mm, 8 mm, 10 mm, and 12 mm

■ Meets the requirements of NGV 3.1, ISO 15500, and ECE R110.

■ For use on standard fittings and valve bodies as well as AbT bulkhead bodies. (Not intended for use with standard bulkhead bodies.)

■ Visual confirmation on initial assembly.

The AbT fitting's design allows for fitting assembly and reassembly like a traditional tube fitting by using a torque wrench.

Fractional Tubing Material: 316/316L SS or 304/304L SS

|

Tube Size OD x Wall |

Initial Assembly Torque Allowable Range in.•lb (N•m) |

Reassembly Torque Allowable Range in.•lb (N•m) |

|

1/4 x 0.035 in. |

150 ± 13 |

150 ± 13 (17 ± 1.5) |

|

3/8 x 0.049 in. |

270 ± 14 (30.5 ± 1.5) |

350 ± 17.5 (39.5 ± 2) |

|

1/2 x 0.049 in. 1/2 x 0.065 in. |

540 ± 27 (61 ± 3) |

700 ± 35 (79 ± 4) |

Matric Tubing Material: 316/316L SS or 304/304L SS

|

Tube Size OD x Wall |

Initial Assembly Torque Allowable Range in.•lb (N•m) |

Reassembly Torque Allowable Range in.•lb (N•m) |

|

6 x 1 mm |

150 ± 13 |

150 ± 13 (17 ± 1.5) |

|

8mm x 1.0mm |

215 ± 11 (24 ± 1.25) |

280 ± 14 (31.5 ± 1.5) |

|

10mm x 1.0mm 10mm x 1.5mm |

360 ± 18 (40.5 ± 2) |

470 ± 23.5 (53 ± 2.5) |

|

12mm x 1.5mm |

660 ± 33 (74.5 ± 3.75) |

800 ± 40 (90.25 ± 4.5) |

Standardized Pre-assembly For Fast & Repeatable Final Installation

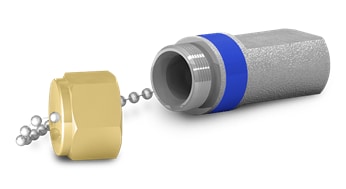

Pre-swaging tube fitting ferrules to the tube prior to assembly eases installation of tube fittings. After pre-swaging, the AbT fitting assembles quickly with commonly available torque tools, facilitating assembly in tight spaces.

1/4 and 6 mm size pre-swage tools

1/4 and 6 mm size pre-swage tools 3/8, 1/2, 8mm, 10mm, and 12mm size pre-swage tools

3/8, 1/2, 8mm, 10mm, and 12mm size pre-swage tools

High-volume Swaging Unit (HVSU), available for all AbT sizes