: Applications for the GB Series Ball Valve

Application for the GB Ball Valves

Swagelok GB ball valve, the full-bore, bidirectional flow–capable ball valve. The valve is engineered to provide flow rates at a working pressure of 6000 psig while simplifying installation, minimizing rework requirements, and delivering the reliable shutoff performance needed to keep workers safe and systems operating efficiently in a variety of demanding applications. The ball valve can be widely deployed as a general-purpose ball valve.

The series ball valve is available in a variety of alloy materials such as 6-Moly, Alloy 2507, and Alloy C-276, as well as materials selected in accordance with NACE MR0175 for sour gas applications. The valve also complies with ASME B31.1 and B31.3 standards for power and process piping systems.

Features

|

ApplicationsThe Swagelok GB series ball valve can be utilized as a general-purpose ball valve. Applications for the valve include:

|

Designed to suit the needs of a wide range of high-flow application in diverse industries and environment.

Valve operates in harsh environmental conditions while providing a cost-effective option for higher-flow applications

- Natural gas systems on tube trailers

- Compressed natural gas storage isolation

- Priority panels

- Bulk transport

- CNG filling stations

- Marine fuel systems

Valve operates in corrosive environmental conditions while containing pressure up to 6000 psig in chemical and refining applications

- Process and instrumentation isolation

- Air distribution manifolds

- High-flow liquid and gas applications

- Highly corrosive applications (e.g., acid service alkylation units)

- Hydraulic applications

Many upstream and midstream oil and gas applications require valves rated up to 6000 psig in a range of sizes and materials

- Process and instrument isolation

- High-flow, high-pressure liquid and gas systems

- Hydraulic packages

- Offshore injection and control packages

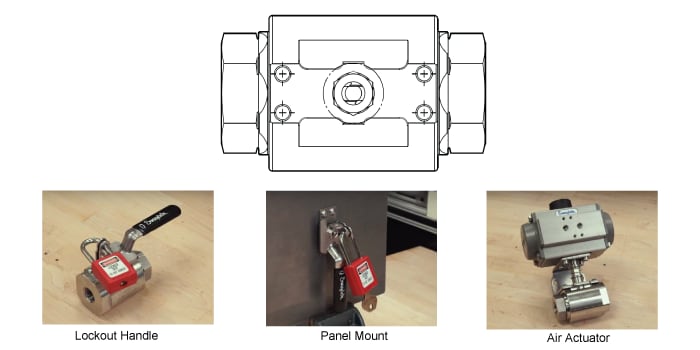

- Fire safety systemsGain inventory and installation flexibility with a valve body featuring a bolt pattern that allows local installation of a lockout handle, panel mount, or ISO 5211 pneumatic actuator.