: Grab Sampling System

As more industries bring additional analytical equipment online, it becomes more imperative to have quality sample systems that can accurately capture the process for later analysis.

Swagelok understands the complex need to have a reliable grab sample system that can be available across multiple sites and between site locations and still support specific application needs. As an industry expert with years of sampling expertise, it was fitting for the company to introduce a safe solution capable of being locally assembled.

- Designed and built with the reliable components you trust from Swagelok

- Local, factory-certified experts for local fabrication and support

- Versatile mounting options for easier installation

- Standard sample systems can be configured using a part number table for simplified ordering

- Additional instrumentation is available, including gauges, meters, and flow indicators

- Backed by the Swagelok Limited Lifetime Warranty

Our standard grab sampling panels are fully configurable, locally built and supported, and reliable, safely capturing accurate, representative process samples and maintaining their chemical composition during storage or transport for later analysis. Our sampling panels not only consistently provide reliable performance, but are also designed to maximize operator safety, ease of use, and uptime.

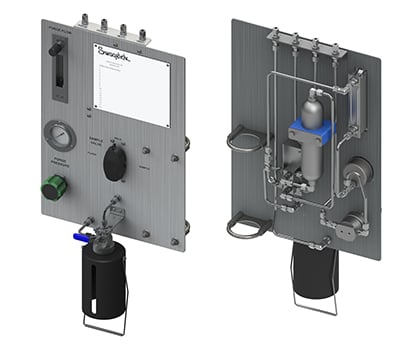

We offer two types of grab sampling systems that provide gas and liquid non-slurry sampling service in consistent, reliable packages. Grab sampling panels assembled by Swagelok technicians can be ordered as a single part number, allowing you to easily purchase sampling solutions that are easy to install, operate, and maintain and that are optimized to perform well in your operations.

- The Swagelok® grab sample module (GSM) is a sampling panel that uses sealed, metal, pressure-containing cylinders to capture either liquid or gas. This closed-loop sampling system uses differential pressure to drive fluid through the sampling system, ensuring fluid is fresh and ready for sample capture.

- The Swagelok® grab sample liquid (GSL) is a liquid-only sampling system for drawing fluid into a non-pressure-containing laboratory bottle with a self-sealing septum cap in applications where the process fluid is not at risk of fractionating or evaporating when stored at atmospheric pressure.

Designed by Swagelok Engineers. Optimized for You.

All Swagelok grab sampling systems are designed to protect both your personnel and your profitability, then configured locally by fluid system specialists to meet your specifications.

Designed for Safety

Swagelok grab sampling systems separate the process pressure from the sample bottle and user, preventing overfilling and overpressure conditions. Our panels are also designed with features to minimize the opportunity for operator error, such as a spring-return handle on the sample draw mechanism of the GSL that prevents unintentional dispensing.Swagelok grab sampling systems are designed to reduce the number of sequencing steps required for sampling and are built for streamlined maintenance, as well. A switching valve configuration on GSM and fixed-volume GSL panels allows for simultaneous control of fluid routing and gives a clear indication of sequencing to the operator and components such as gauges can be isolated during maintenance to minimize downtime.

Closed-loop GSM sampling panels provide fresh samples to cylinders that hold samples at the same process conditions that existed during sampling, giving confidence that the sample is representative. A GSL can use glass laboratory bottles that provide immediate feedback on the visual quality of a sample stream. All our grab sampling panels are assembled with Swagelok tube fittings, reducing potential leak points.

Accessible Grab Sampling Support

Our highly trained engineers and technicians will work closely with you to determine the right type of panels and proper configurations to meet your specific needs. Once they have assessed your current systems and discussed your sampling requirements, they will recommend, configure, and assemble grab sampling panels that meet your specifications.

Sampling System Evaluation and Advisory

Want an even deeper analysis of your sampling systems and practices? Our Swagelok® grab sampling evaluation and advisory services team can visit your facilities to help you:

- Improve operational performance

- Eliminate potential safety and environmental concerns

- Achieve more representative samples on a regular basis

Sampling System Training

Our sampling specialists can also help equip your team with the knowledge to prevent, diagnose, and eliminate costly issues with Swagelok® sampling system training based on the teaching of industry expert Tony Waters:

- Process analyzer sampling system (PASS) training

- Process analyzer sampling system (PASS) subsystem training

- Sampling system problem solving and maintenance (SSM)

Swagelok Assembly Services

Improve your current sampling systems reliability with our expert, in-depth evaluation of your sampling systems, from tap to grab sample station.

Our fluid system design experts are prepared to assist throughout the solution development process. We can follow your existing design, or you can work with our tech center to develop a new or revised one. In any case, our approach is collaborative, as we work closely with you to ensure we understand the problem and are developing the configuration that most completely meets your needs.

Whether you have a preliminary drawing or just the glimmer of an idea, it's not too early to consult with our fluid system experts to receive:

- CAD drawings

- Piping and instrumentation design (P&ID)

- Component selection and sourcing

- Bills of materials (BOM)

- Professional services, such as bending and welding

- Testing of system performance

- Professional packaging and delivery

You trust our components. Now trust our experts to create great fluid system assemblies.