Swagelok Valves | High-Quality Flow Control & Industrial Valve Solutions

Swagelok Valves

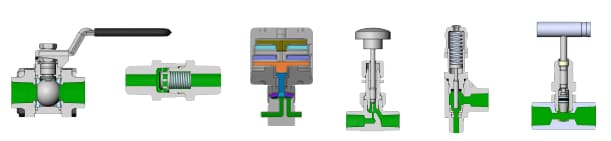

Swagelok offers a wide range of valve types. The key to selecting the right valve is to match it with the required function and ensure it suits the application. Consider factors such as fluid type, pressure, and operating temperature. Swagelok valves can be categorized based on their function as follows:

1. On-Off Valves – These valves are designed specifically for open and close control. Ball valves are ideal for quick shutoff applications but are not suitable for throttling or flow regulation. In contrast, plug valves provide both on-off control and some level of flow regulation

2. Flow Control Valves – Valves designed to regulate or throttle flow rates, available in various models depending on the required level of control precision

On-Off and Flow Control Valves

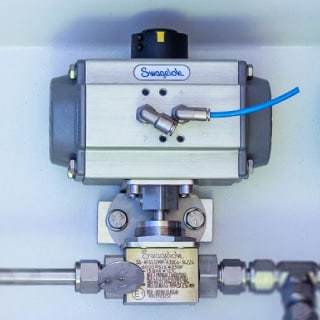

Ball Valves and Quarter-Turn Plug Valves

Swagelok ball valves ensure reliable on-off operation, while plug valves offer a compact, low-maintenance design. Both provide leak-tight performance for various applications

Needle and Metering Valves

Swagelok Needle and Metering Valves used in general applications that require precise flow control within fluid systems

Diaphragm Sealed Valves

Designed for high-purity applications requiring precise fluid flow regulation

Bellow Seals Valves

Ideal for high-purity applications where ultra-precise flow control is not a primary requirement

Atomic Layer Deposition (ALD) Valves

Engineered for high-purity applications with high-cycle operation, particularly in the semiconductor industry. These valves offer rapid response times, precise gas delivery, and excellent thermal stability

3. Directional Control Valves – Valves designed to regulate fluid flow direction as required. Selection depends on the number of flow paths needed, such as 2-way, 3-way, or 4-way configurations. Check valves are used to prevent reverse flow, ensuring fluid moves in the intended direction. Swagelok offers a wide range of directional control valves to suit various applications

4. Relief Valves, is a safety device that automatically releases excess pressure from a system when it exceeds a predetermined limit, preventing potential damage or hazard

If you need assistance in selecting the right valve type, size, or Cv calculation, our technical engineering team is here to help. Contact Swagelok Thailand here!

Directional Control and Relief Valves

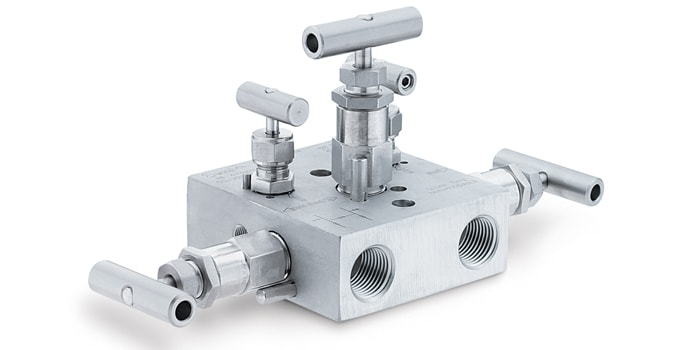

Manifolds

Swagelok manifolds feature a compact design that reduces size, weight, and leak points while ensuring easy installation and maintenance

Check Valves

Swagelok check valves are designed for one-way fluid flow, available in various designs like poppet, lift, and all-welded, suitable for general-service and high-purity applications

Process Interface Valves (DBB)

Swagelok process interface valves or Double Block and Bleed (DBB) ensure a seamless transition from process to instrumentation systems in a compact design, reducing size, and leak points

Quick Connects

Swagelok® quick connects enable fast, tool-free connections with push-to-connect coupling. Available in various configurations, they offer options like single- and double-end shutoff, full-flow, miniature, and PTFE-sealed designs

Relief valve

safety device that automatically releases excess pressure from a system when it exceeds a predetermined limit, preventing potential damage