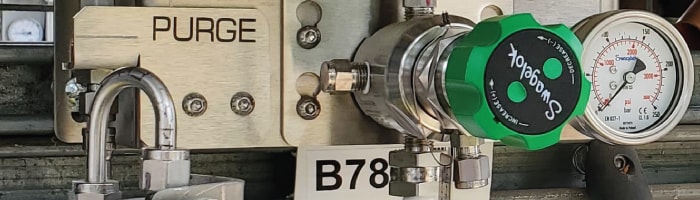

Swagelok Regulators

Learn how to identifying and solving common pressure regulator issues

It is important for industrial fluid systems to have precise temperature, flow, and pressure settings to operate properly. Achieving this precision requires several key components, but one of the most essential components is a pressure regulator. When regulators are not properly maintained and fail, pressure may fluctuate significantly downstream,

What happens if a pressure regulator malfunctions or stops working? The key is to identify a failing pressure regulator before it becomes a bigger problem.

Use this step-by-step guide to troubleshoot some of the most common problem with pressure regulator.

Step 1 Understand Process Specific Needs to confirm that you have the correct regulator for your application

Before you perform a regulator assessment, you should identify what process requirements are involved such as system flow, pressure, temperature, process sensitivity and system media. This evaluation will provide the necessary insights into whether the regulator in question is suited for the specific application.

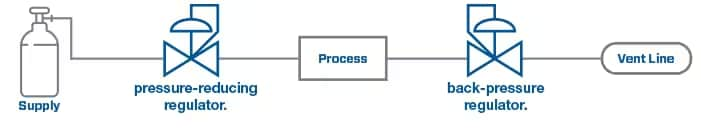

Pressure-reducing regulators control pressure from a source before it arrives at the main process. If you need to control your downstream process pressure, then you need a pressure-reducing regulator. A pressure-reducing regulator’s main purpose is to maintain a steady downstream pressure in a fluid system application.

In the other way, a back-pressure regulators control pressure upstream. If you need to control your upstream process pressure, then you need a back-pressure regulator. Once the proper regulator has been identified and installed, it is time to accurately determine the problem issue. Is pressure dropping below the set pressure downstream or is it rising beyond the set pressure upstream?

Step 2 Identify your issue and fix

If pressure dropping below target pressure, Unwanted pressure drop, or droop is commonly caused by undersized regulator or maybe incorrectly set pressure spring and range.

If pressure is rising beyond your set pressure, either creep or the supply pressure effect (SPE) is likely at play.

|

If the pressure is dropping or droop, it is likely because the regulator is undersized for the application’s flow requirements. Recommended Option: : Select a set pressure range closer to the required set pressure : A dome-loaded regulator may be a better option. This type is more resistant to flow changes and can help better maintain pressure in applications where flow varies : A regulator with a larger flow coefficient can help prevent unwanted outlet pressure drop Using a flow curve generator tool, which the regulator supplier should be able to provide, will help operators determine if the regulator is properly sized for the application. |

|

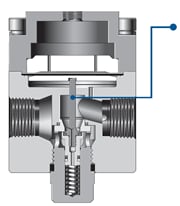

SPE can be identified when a change in outlet pressure occurs because of a change in the inlet (or supply) pressure. If the inlet pressure drops, outlet pressure can increase beyond what downstream components are expected to handle. Recommended Option: : Installing two single-stage regulator : A balanced poppet design can help minimize the area where high inlet pressure can have an impact, mitigating SPE |

|

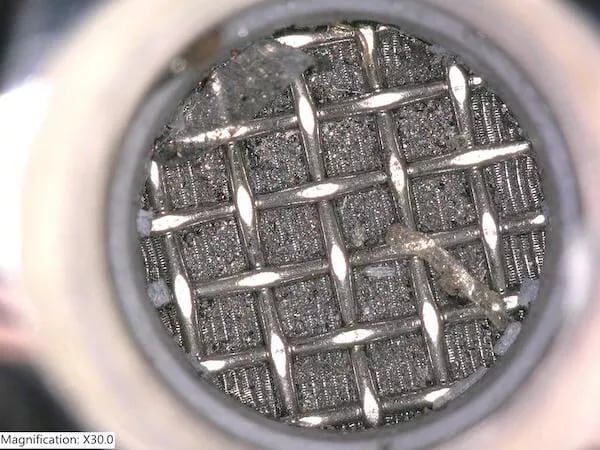

Creep occurs immediately after regulator installation when debris flows through the system. The contaminants create a fine gap between the regulator’s seat and poppet, which can inadvertently cause system media to flow across the seat. The result is unwanted pressure increases downstream, which can be dangerous if the downstream components are not rated to handle the higher pressures. Recommended Option: Creep can be avoided with careful installation, upstream filtration, and the purchase of a spares kit with new regulators : Installing an inlet filter upstream of the regulator can reduce contamination : Installing a relief valve can protect downstream processes from damaging over-pressurization |

Common problem that can be found

Crack

A cracked diaphragm will limit how well a regulator can sense pressure, lowering its ability to control pressure

Clogged

Sometimes, the problem is as simple as cleaning or replacing a clogged filter, offering a lower-cost alternative to replacing the entire regulator

Regulator selection

Selecting regulators for your site process or gas distribution needs can get extremely complicated, with many factors to take into account. Our regulator experts assist customers on a daily basis and can help extend the reliability, uptime and safety of your systems.