: How to Maintain Your Hose and Extend Its Life

How to Maintain Your Hose and Extend Its Life

Proper hose installation is essential in guaranteeing excellent hose performance. Installing a hose may seem simple but installing it the wrong way will shorten its lifespan considerably. By following the guidelines below when installing your hoses, you will ensure a longer time between the installation and the replacement of a hose.

Here are simple ways designers keep plants running and minimize potentially dangerous situations involving hoses.

Match hose type to application

Increasing production often puts greater demand—and stresses—on industrial hoses. In cases of high demand, make sure hose specifications for pressure, temperature, and chemical compatibility are up-to-date and inspected regularly. When specifying a hose, follow the considerations outlined in this article to ensure the hose type is properly matched to its intended application.

Properly route hoses to eliminate strains

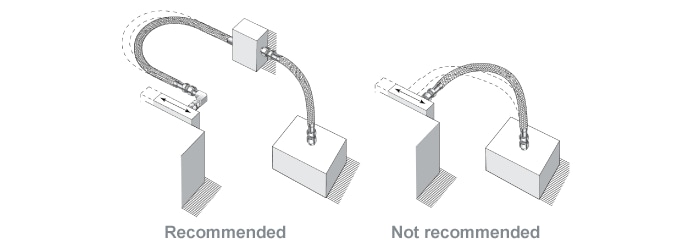

Even if all the right choices have been made in choosing the right the hose material and type for its given application, improper installation and routing can cause hose failures and, in turn, greater risks to workers and equipment.

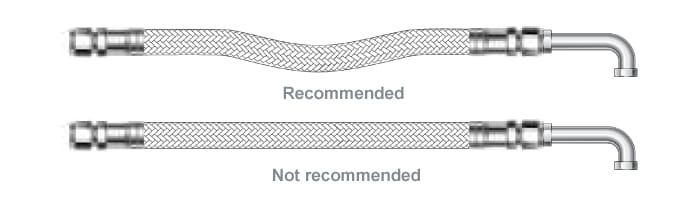

One common installation error involves improper hose length. If the hose is too long, it can lead to accelerated wear from rubbing against itself or a machine. Inversely, if it is too short, stretching it too far to make it fit can create leaks at the end connections as a result of regular operating conditions such as thermal expansion, pressure changes, or other movements. The proper hose length has enough slack to handle connection point movement, but not enough to allow for rubbing, interference, or kinking.

Some other common strain sources include:

Electrostatic Discharge

Static electricity can be generated by fluid passing through the hose. Select hose with sufficient conductivity to ground the static electric charge and allow static dissipation. If static electricity generation is possible within an application, choose static dissipative hose and properly ground to earth.

Vibration

Evaluate amount of system vibration when selecting hose. Metal hose may not be appropriate for systems with constant or severe vibration.

Length

Take into consideration hose movement, system pressurization, and thermal expansion when determining hose length. Installing hose that does not have sufficient length to accommodate these factors may reduce hose life.

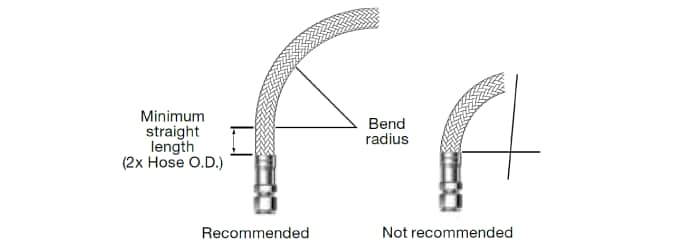

Minimum Bend Radius

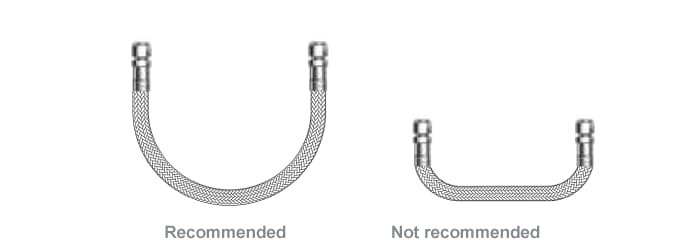

Follow minimum bend radius requirements for your hose. Installing hose with smaller bends may kink hose and reduce hose life.

Hose rupture or leakage may result from bending too close to the hose/fitting connection.

Hose Strain

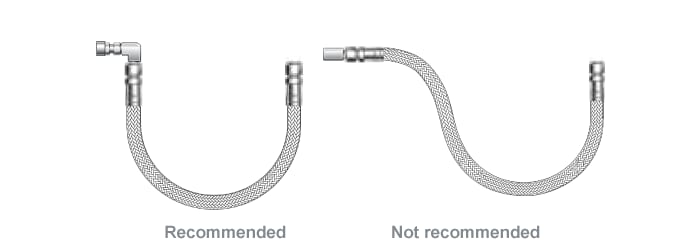

Elbows and adapters can be used to relieve hose strain.

Machine Tolerance

Allow for changes in length resulting from machine motion and tolerances.

Bending in One Plane

Avoid twisting the hose by bending it in one plane only. For a compound bend, use multiple hose pieces or other isolation methods.

Swagelok Knows Hose.

See How You Can Benefit

The right hose keeps your process performing safely and cost effectively. The wrong hose could undermine your process, put people at risk, and compromise your bottom line – sometimes without you being aware of it.

Our Hose Advisory Services can help you identify this problem and much more.

Let Our Services Come to You

Swagelok Evaluation and Advisory Services put experienced industry experts in your plant with one goal: improving the reliability and safety of the operation. We will evaluate your fluid system health to keep thins flowing smoothly.

Find more information about hose product and services

Hoses and Flexible Tubing

Swagelok hose and flexible tubing is available in custom lengths, in diameters 2 inches and under, and with a wide variety of end connections. Choose materials and end connections for a wide range of pressures and temperatures.

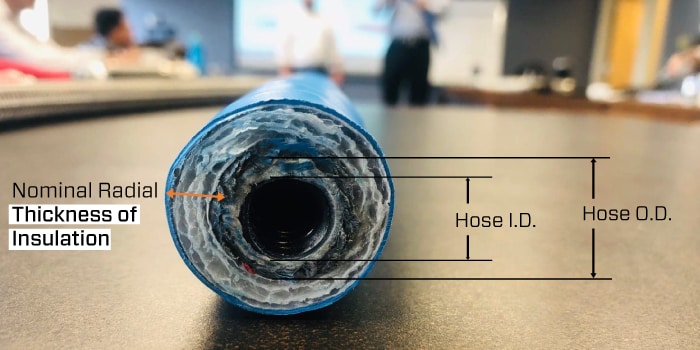

Consideration for Hose Insulation

Hose insulation help keep system fluid inside the hose at desired temperature levels. Before selecting insulated hose, there are couple thing you should consider.