: Material Science Training

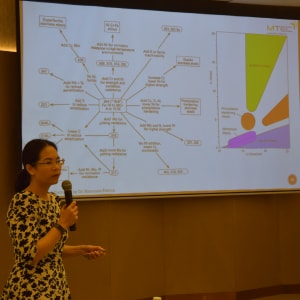

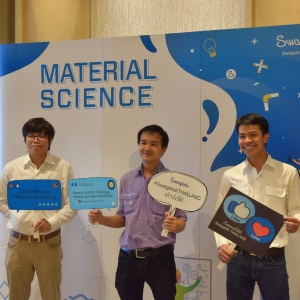

Material Science Training & Material Corrosion Workshop

Organized by: Swagelok Thailand in corporate with National Metal and Materials Technology Center (MTEC) by NSTDA

In Oil and Gas and petrochemical industry, requires the safe and profitable. The extreme environments of some of these unique prospects challenge the boundaries of traditional engineering alloys, as well as our understanding of the underlying degradation mechanisms that could lead to a failure.

Despite their complexity, high-pressure and high-temperature, deep and ultra-deep, pre-salt, and highly acid chemical represent the most important source of innovation regarding materials technology, design methodologies, and corrosion control strategies.

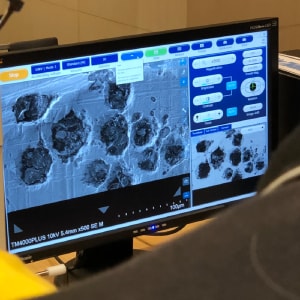

Material Science Training provides an overview of trends in materials and corrosion, with focus in oil and gas production and chemical and refinery application. The aims of this seminars focused on selecting corrosion-resistant materials and corrosion protection of all parts for projects in the oil and gas, and petrochemical plant. Moreover, provide a better understanding on the NACE® sour gas standard and how specific alloys resist corrosion.

Thanks for your TRUSTED…

Find more information about Material Selection

Material Selection Guide

Understand the factors that contribute to corrosion and the materials that help fight it.

Field Engineers

Swagelok field engineering stands ready to work with you to solve you problem and develop the best solutions for your fluid system.

Onsite Services

Boost system safety, performance, and efficiency with prioritized, actionable recommendations from Swagelok experts based on fluid and sampling system site surveys, hose advisors' observations, or steam system audits