: Fluid System Evaluation & Advisory Service, FSEAS

Fluid System Evaluation and Advisory Services, FSEAS

Discover the Benefits of Fluid System Evaluation and Advisory Services

Swagelok® Fluid System Evaluation and Advisory Services (FSEAS) brings our technical expertise, application experience, and industry knowledge onsite to your facilities, helping optimize your safety, productivity, and profitability.

Our certified Onsite service engineer can help you diagnose and resolve fluid system issues to improve operational performance, reduce cost and labor time, and help control safety, quality, and environmental challenges.

What we do:

Our fluid system experts will evaluate

• Specific components such as fittings, tubing, hoses, valves, and gauges for best practices to ensure fluid system operation

• Gas systems for opportunities to reduce leaks

• Overall fluid system health for maximum uptime including leak, corrosion and improper installation that cause unsafety issue

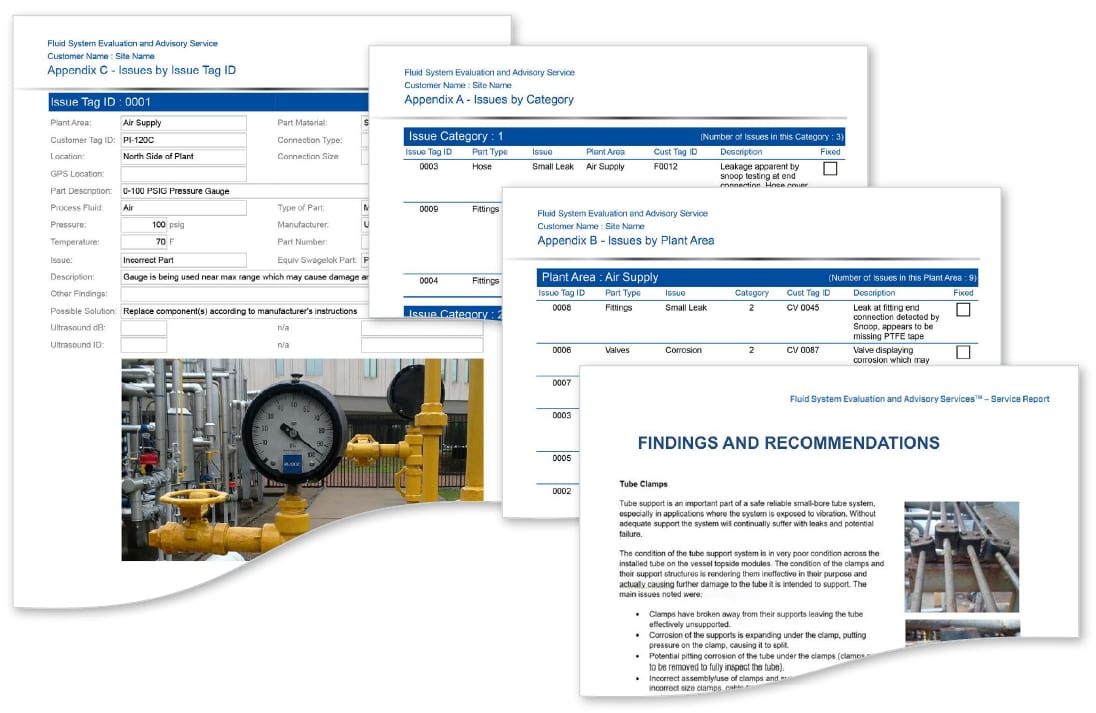

During the inspection, colored identification tags with numbers were used to identify system components for the report; these tags were left on the component for identification purposes. The tags colored is used to identify risk and/or priority of each issue. Upon completion of our onsite services, you will receive a comprehensive report that make your job easier to do a Shutdown Turnaround planning and scheduling.

How FSEAS program benefit to your Shutdown Turnaround Plan:

Effective Planning – creating an effective shutdown turnaround plan, you need to set a scope of area, assets or equipment to cover. Testing and inspecting before repairing and replacing will help you to create effective planning, scheduling and organizing work and resources.

Swagelok Fluid System Evaluation and Advisory Services report will give you a comprehensive data to create an effective plan. Photos with clearly identify locations of problem and color taqs will be useful to categorized and prioritize your job, manpower and resources.

Cost saving – Plant maintenance shutdown or turnaround dramatically impact on maintenance costs and bottom-line profitability of process plant. Because maintenance cost are the result of manpower, equipment and material. Keep manpower and equipment usage efficient, and you will control your Shutdown Turnaround Plant Maintenance costs effectively.

Rising your plant efficiency – good preventive maintenance can help to reduce unplanned shutdown or downtime.

Safety - Protecting your people, systems, and reputation starts with avoiding exposing team members to hazards related to improper fluid system design, installation, an maintenance, as well as leaks. We provide recommendations to fix issues that could cause potential safety incidents.

Optimize Resources…

If you're being asked to do more with reduced budgets and fewer experienced staff, we can help you streamline system installation, identify lower-maintenance components and designs, improve production profitability, and train your team. We provide:

· Repair prioritization

· Fabrication and assembly services

· Product selection consulting

· Bill of material (BOM) and piping and instrumentation diagram (P&ID) generation

· Customer training on best practices

· Preventive maintenance recommendations

Promote Safety

Protecting your people, systems, and reputation starts with avoiding exposing team members to hazards related to improper fluid system design, installation, an maintenance, as well as leaks. We provide recommendations to fix issues that could cause potential safety incidents or violation through:

· Leak Identification

· Design risk evaluation

· Product selection assistance

· Fluid and sample system analysis

· Training and process recommendations

Reduce cost, Increase Uptime and Reliability

If equipment downtime hurts your production revenue, strains your repair budget, and takes team member away from other important focus areas. Swagelok, we can help you reduce cost, increase up-time and reliability:

· Design optimization opportunities

· Detect leak and potential failure point identification

· Hose selection, installation and maintenance recommendations