Sample Cylinder Inspection Service

Sample Cylinder Inspection Service

Ensure Your Sample Cylinders are

Inspected. Tested. Safe

Sample cylinders are heavily used items in process facilities and typically go through a lot on their journey from the sample point to the laboratory. They are handled by a variety of plant personnel, including technicians, operations, and laboratory staff. Cylinders may be connected and disconnected from a sample point multiple times per day. Throughout all of this, your cylinder can become critically damaged over time and thus may pose a safety risk in your facility.

Swagelok Thailand, we offer a Sample Cylinder Inspection Program as a quality assurance services that includes a full assessment of the cylinder to ensure quality and safety operation at your facility.

Benefit of Swagelok Sample Cylinder Inspection Program:

- Increase operator safety by identifying and elimination unsafe sample collection methods

- Increase profitability by collecting more representative samples with allow for more accurate process monitoring.

- Additionally, properly assembled sample cylinders increase the efficiency of sample gathering.

What can we do for you?

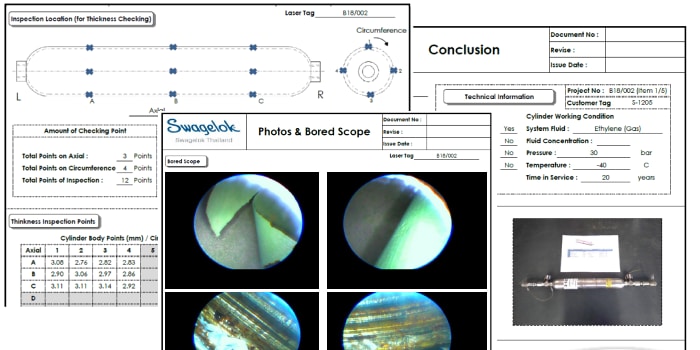

1. Outside Visual Inspection

We will inspect your cylinders and any related assemblies to ensure that the cylinder has not been deformed and is still within tolerance to operate safely under pressure. Then we assess the conditions of threads, needle valves, rupture disc valves, and fittings.

2. Leakage Testing

We will run a nitrogen test@10 bar (147 psi) and check leakage point using Snoop leak test solutions. Then using an Ultrasonic Leak Detector to quantify leak. An average thickness of a cylinder will be calculated from 12 measurement points.

3. Thickness Inspection

Thickness test indicate the consistency inside of the cylinder that effect to pressure tolerance.

4. Pressure Testing

Pressure test is carried out to ensure that the cylinder maintain their integrity and resistance to the pressure. We will run a sequence step of pressure based on a customer working pressure as example below. The maximum pressure that we can tested is up to 68.9 bar.

5. Inside Borescope Checking

Damage inside of cylinder is checked using a borescope. We can check a remaining chemical residue compound, corrosion, deep scratches, inside cracking, and verify Sulfinert® or PTFE coated condition inside of the cylinder.

Upon completion of the inspection, we will provide you with a detailed report including images, with recommendations on needed repairs and tests if required. All inspected cylinder will be stamped with tested date as part of quality control process

|

"Taking advantage of this program to increase safety an integrity of your plant” Reserve our schedule for cylinder maintenance program or find out more about how Swagelok Thailand can help you improve your sampling reliability and safety through sampling system evaluation and advisory service program, sample bomb assembly and cylinder inspection services, contact our team: |

Sample Cylinder Assembly Service

Sample Cylinder Assembly Service

Our certified Field Engineers have a deep understanding with gas and vapor sampling applications in Oil & Gas and Petrochemical refineries. They are readily available to perform an onsite consultation to understand your process and suggest customized solutions to meet your specific sampling requirements. We can help you determine proper materials of construction, valves, quick connects, and accessories to provide you with the gas and vapor sampling reliability you need.