Design and Assembly Services

Why should you have to assembly all of the component?

We gather the necessary parts from Swagelok and Non-Swagelok, build the assemblies and manage all inspection, packaging and deliver a complete solutions with limited lifetime warranty.

Swagelok®Custom Solutions refers to our expert capability to supply assemblies and fabrications using Swagelok products and other customer-specified components.

Whether you have a preliminary drawing or a simple idea, it’s never to early to consult with our team of experts. We are at your service to create assemblies that meet the unique need of your application.

From Basic to System, we can assembly for you

Save Time With Standard and Configurable Assemblies

Swagelok design, fabrication, and assembly experts have worked with businesses across the globe to add efficiency and reliability to their operations by delivering reliably designed and constructed fluid system assemblies. Standard assemblies we’ve developed include:

Analytical Subsystems

Pre-engineered and preassembled fluid sampling and control subsystems, such as fast loops, field stations, calibration and switching modules, sample probes, and fluid distribution headers, bring efficiency and consistency to your operations. Swagelok® pre-engineered subsystems minimize system footprints, simplify system design, and promote representative samples and accurate analytical results

Gas Distribution Systems

We evaluate existing gas distribution systems and build standardized, configurable gas delivery systems to help protect system operators, increase process uptime, and improve process accuracy and repeatability.

Grab Sampling Systems

Customizing Swagelok® grab sampling systems allows for safe, efficient sample capture while meeting your specific plant application needs. The panels are available in a variety of configurations and advanced features

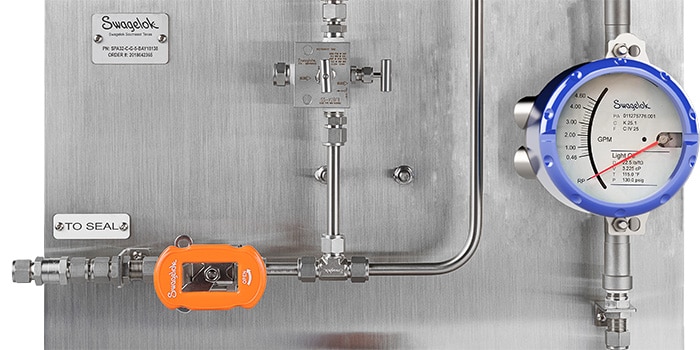

Mechanical Seal Support Systems

Swagelok®seal support systems are guided by API 682 and are offered as kits and assemblies. These systems reliably supply either gas or liquid to the mechanical seal to regulate the environment in which the seal operates, increasing longevity

Receive as Much Design Support as You Need

Our fluid system design experts are prepared to assist throughout the solution development process. We can follow your existing design, or you can work with our tech center to develop a new or revised one. In any case, our approach is collaborative, as we work closely with you to ensure we understand the problem and are developing the configuration that most completely meets your needs.

Whether you have a preliminary drawing or just the glimmer of an idea, it’s not too early to consult with our fluid system experts to receive:

- CAD drawings

- Piping and instrumentation design (P&ID)

- Component selection and sourcing

- Bills of materials (BOM)

- Professional services, such as bending and welding

- Testing of system performance

- Professional packaging and delivery

You trust our components. Now trust our experts to create great fluid system assemblies.