Chemical and Refinery

Chemical and Refinery Applications

Process and analytical instrumentation are the core of any chemical and refining plant. They help ensure product quality and high yield rates with maximum production throughout your operation. Swagelok is an industry expert when it comes to analytical systems that provide leak-tight, working solutions for complex and corrosive fluid applications. Our company has extensive experience in manufacturing analytical systems, fluid system assemblies as well as a full range of liquid and gas grab sample panels and sample cylinders.

Products for the Chemical & Refinery Industry

Swagelok® fluid system components and assemblies for chemical processing can be trusted to help you minimize downtime, maximize production efficiency, and meet strict standards for emissions control. Our fluid system products are backed by the Swagelok Limited Lifetime Warranty.

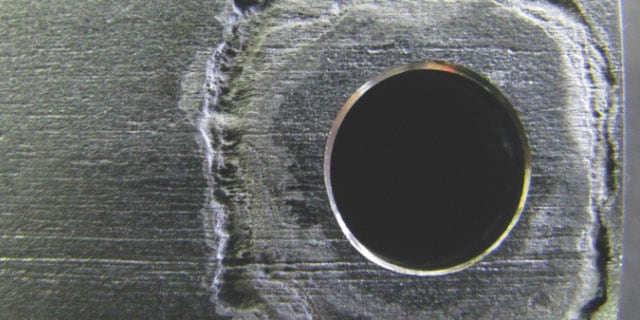

Swagelok tube fittings deliver a leak-tight, gas-tight seal that is resistant to vibration fatigue, even in harsh environments or stressful applications. They withstand high pressures and temperature extremes and are easy to install, disassemble, and reassemble in a variety of situations.

From the far reaches of space to the bottom of the ocean and everywhere in between, trust leak-tight, long-lasting Swagelok valves in your critical applications. Known for durability derived from carefully controlled manufacturing practices, our valves perform reliably even after years of use in demanding applications.

Reliable pressure control is essential to the safe operation of your fluid systems. At Swagelok, we have the right combination of regulators to fit practically any situation, and our advisors can help you find a configuration that will maintain pressure and minimize droop over a wide range of pressures and flows.

Find reliable tubing options with the material properties needed for your application. Make sure your system is built to last with tubing accessories that help you cut, bend, deburr, and support tubing so it provides leak-tight performance.

Swagelok hoses and flexible tubing are trusted to perform in industrial facilities worldwide, transporting liquids and gases that are crucial to operations. Choose from a variety of core materials, reinforcement styles, end connections, or insulation options to find products that suit the pressures and temperatures of your applications.

Swagelok offers a wide selection of sample cylinders that are compliant with various transportation industry standards related to chemical transfer. These durable, pressure-rated metal cylinders also prevent samples from escaping during grab sample system operation and are easy to clean.

Contaminants can lead to off-spec products and other problems downstream, but the right fluid system filters can help you avoid these issues. If your operations could benefit from the removal of liquid or particulate contaminants from your fluid systems, Swagelok filters can help you achieve reliable system function and repeatable results.

Swagelok's PTX series transducers and VCM digital control module smart products work together to capture and report the critical flow, temperature, and pressure of process samples destined for process analyzers.

Increase efficiency and decrease footprint with Swagelok analytical miniature modular systems. These modular platform components and systems reduce design and assembly time and yield reliable results.

Services for the Chemical & Refinery Industry

We provide a variety of services to chemical companies that help them minimize downtime, improve process efficiency, avoid leaks, and trust their analytical instrumentation. Look to Swagelok specialists for help building custom fluid system assemblies, consulting on system designs, addressing fluid system issues, and delivering training to your team members.

Onsite Services

Onsite Services

Faulty fluid systems consume financial resources and the time and attention of technicians needed elsewhere. Swagelok shares advice for engineering a more efficient operation, from improved maintenance practices to making systems smarter. Fabrication and Assembly Services

Fabrication and Assembly Services

If you are experiencing issues with the performance of existing fluid systems or simply lack the resources to design and build reliable subsystems, our local specialists can engineer and fabricate kits, assemblies, and subsystems optimized for your operations. Field Engineering

Field Engineering

Swagelok-trained professionals can help guide component, material selection and system design from afar or visit your onshore or offshore facilities to evaluate your fluid systems, providing detailed recommendations on installation practices and system enhancements. Fluid System Training

Fluid System Training

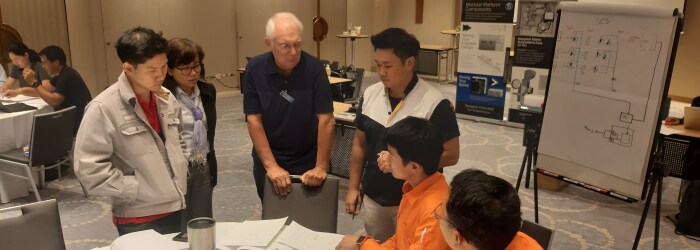

We can provide the knowledge needed to keep your fluid systems operating safely and effectively with training covering fluid system design, installation, operation and maintenance, materials science, welding, fluid sampling, and more.

Design & Assembly

Take Fluid System Design and Assembly Off Your To-Do List

Our assemblies are locally built with Swagelok's high-quality fluid system components. We can also incorporate third-party products, including wiring, automation, transmitters, relays, motors, and more. We produce professional-grade, reliable solutions, complete with testing, inspection, and packaging, all backed by the Swagelok Limited Lifetime Warranty.

Swagelok Custom Solutions are fabricated assemblies that range from systems with just a few components to full panels, enclosures, and beyond. We can follow your design or develop a new one with our custom engineering services.

Process Instrumentation

Save Time With Standard and Configurable Assemblies

Swagelok design, fabrication, and assembly experts have worked with businesses across the globe to add efficiency and reliability to their operations by delivering reliably designed and constructed fluid system assemblies. Standard assemblies we’ve developed include:

Standardization, product selection assistance, and vendor-managed inventory can free your team to focus on operations instead of procurement issues or organizing spare parts and components from different suppliers.

Standard Swagelok® grab sampling systems allows for safe, efficient sample capture while meeting your specific plant application needs. The panels are available in a variety of configurations and advanced features

Pre-engineered and preassembled fluid sampling and control subsystems, such as fast loops, field stations, calibration and switching modules, sample probes, and fluid distribution headers, bring efficiency and consistency to your operations. Swagelok® pre-engineered subsystems minimize system footprints, simplify system design, and promote representative samples and accurate analytical results

We evaluate existing gas distribution systems and build standardized, configurable gas delivery systems to help protect system operators, increase process uptime, and improve process accuracy and repeatability.

Swagelok®seal support systems are guided by API 682 and are offered as kits and assemblies. These systems reliably supply either gas or liquid to the mechanical seal to regulate the environment in which the seal operates, increasing longevity

More information about Swagelok Solutions

INEOS Petrochemical Safety Case Study

Swagelok's contribution to the safe operation of INEOS's petrochemical facility in Cologne, Germany maps back to the close collaboration between the two companies. Learn how Swagelok's trusted reliability helps INEOS ensure petrochemical safety.

Fine-Tuning for Optimum Performance

Fine-Tuning for Optimum Performance

Swagelok prepares process analytical engineers, technicians, and maintenance personnel to catch mistakes before they happen. Our experts will teach yours to recognize existing problems in installed systems, fine-tune for optimum performance and, ultimately, provide a timely result that is representative of the fluid in the process line at the time the sample was taken.

Analytical Instrumentation training covers most everything a learner needs to know about process analyzer systems—from basic chemistry through sampling system design and build, all the way to system troubleshooting and optimization.

Learn more:

Swagelok

Swagelok Swagelok

Swagelok

Swagelok

Swagelok Grab Sampling Systems

Grab Sampling Systems Analytical Subsystems

Analytical Subsystems Gas Distribution Systems

Gas Distribution Systems