: Why System Performance Depends on Proper Tube Preparation

Why System Performance Depends on Proper Tube Preparation

November 18, 2019 | Andrew Hitchcock, Associate Product Manager, Swagelok

Quality tubing and highly engineered fittings form some of the most critical connections in any refinery. A number of variables must be considered when ensuring each of these connections is optimal—material type, tube size, wall thickness, material properties, site specification, and more.

Just as important to the successful operation of a fluid system, though, are sound practices when technicians are putting these connections together. One of the most common causes of tube and fitting failure is improper installation. Proper tube handling and preparation techniques—which all take place before the fitting is tightened—are essential for safe, leak-tight and long-lasting connections that plant operators can trust.

How do you ensure refinery maintenance staff are trained, armed, and prepared with the right information and tools to make quality connections throughout the plant? Here are a few of the most important things to consider.

What Is at Stake?

No one likes the loss of profitability or a dip in operational efficiency, but these are not the most pressing fluid system leak-related concerns. Many customers work in inherently dangerous applications where the risk of incorrect installation can result in serious injury or worse. Leaks in low-pressure water or air systems typically have very little safety threat associated with them and are often viewed as an inefficiency-related inconvenience. However, a loss of air pressure could result in a safety-critical valve failing to open at the right time. Further, if a system is leaking a hazardous gas such as hydrogen, even a small leak could have severe consequences. Since these dangerous gases and chemicals are essential to the fabrication of many products, they cannot simply be removed from a plant’s operations, and when lives are on the line, it is paramount that they stay appropriately contained.

Beyond safety concerns, leaks related to improper tube preparation can be significant contributors to lost production. In some cases, this comes in the form of system inefficiency, and the longer that system runs at less than optimal levels, the more potential profit the business loses. Leak-related loss can come in other forms as well. If chemicals or gases are leaking out of a system, it not only creates a potentially hazardous situation, but a costly one as raw material is wasted. Even a simple air leak, which is often ignored, can be costly if it means spending more money to run your equipment. Many companies buy or rent air compressors as their compressed air needs rise, but if they fixed leaks or otherwise optimized their tubing setup, they could get by with less equipment and lower energy costs.

Some costs of fluid system leaks are obvious, while some are hidden. In any case, they are often avoidable if you know the common causes of failure.

Recognize Common Causes of Failure

One of the primary reasons fluid systems develop leaks is improper tubing preparation. For example, someone might not cut the tubing squarely, creating an angled end. Alternatively, there could be burrs on the end of the tubing because it was not properly deburred or filed down after being cut, which could jeopardize a seal. Filing a metal tube end after cutting it with a hacksaw may seem like an unnecessary extra step, but when we look at empirical data from system failures, we find that something this small is often a root cause of issues. Taking the time to perform proper tubing preparation and installation can prevent major headaches later.

Tubing that has not been properly deburred.

Tubing that has not been properly deburred. Tubing cut and deburred properly

Tubing cut and deburred properly

Minimizing fluid system failure often comes down to having the proper tools available and avoiding negligence that can cause damage to installed systems. There are multiple scenarios that often lead to someone not using the right tool for the job when installing components or when fixing fluid systems. In some cases, specialized tools for making accurate, square, burr-free cuts are available but are not used when it would be faster to take a shortcut. In other cases, a worker may simply not have proper tube facing equipment available to ensure burr-free tube ends. That said, the proper tools for tube cutting and deburring are easy to come by, and a relatively minor investment can help avoid costly failures.

There are two common negligence-related causes of fluid system leaks:

- Scratches, nicks, or dents on the tube, often a result of improper handling. Generally, this sort of damage results from improper handling. For instance, a worker might grab the end of a 20-foot-long piece of tubing, pull it out of the tube container, cut off 6 feet, and then slide the remaining 14-foot piece back into the rack. If there is a burr or scratch on the cut piece, this will cause scratching of the tubing still in the rack. Tubing is also easily dented if it is pulled off the rack and an end hits the ground; it can be scratched if it is dragged from point to point. It is important for technicians to inspect tubes for these defects before installation, but this step is often skipped, or seemingly minor damage is overlooked.

- Improper preparation of tubing, including not cutting at a square angle or not deburring the end of the tube. As noted earlier, proper tube cutting is an important step in successful fluid system assembly. Hacksaws or tools designed specifically to cut tubing are most commonly used, and as long as care is taken during cutting, achieving a square cut is relatively easy. More prevalent issues tend to arise with deburring, which can be done with a specialized deburring tool or something like a rasp or file. This step in the process is either skipped entirely or executed improperly due to lack of availability of proper tools.

Arm Your Team with the Right Training

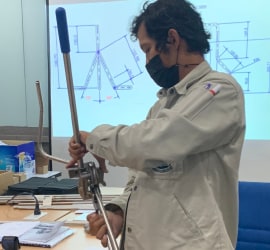

The common issues with tube preparation outlined above are easily avoidable. Ensuring your organization does not fall victim to fluid system failure or leakage may simply come down to having your employees undergo proper tube fitting installation training. Equipment manufacturers can help here: the training Swagelok offers, for instance, covers different tube handling and tube inspection practices in depth, ensuring workers are using practices that minimize rework and scrap.

Even before bringing in tube fitting training experts, you can avoid many issues by taking a hard look at material handling and tube preparation practices throughout your organization. Do you see people carrying out tube fitting processes incorrectly? Do you see something that could be corrected by addressing it at a startup meeting or via one-on-one conversation? This sort of self-analysis is a good initial step toward more efficient, safe operations, and it is something regularly covered in Swagelok tube fitting training.

Fundamentally, addressing tube handling and preparation problems comes down to awareness. Employees may not know that pulling a length of tubing out of a rack can cause significant problems down the road, so a little education can go a long way. Your staff needs to know that while a successful tube fitting connection depends on many different things, a key success factor is how well they have prepared the piece of tubing to go into the fitting.

Do not let little mistakes create large safety and efficiency problems for your company. Be sure your whole team is educated on how to promote optimal operations with proper tube preparation.