Fast Loop Modules

Fast Loop Modules

Why Use a Fast Loop Module?

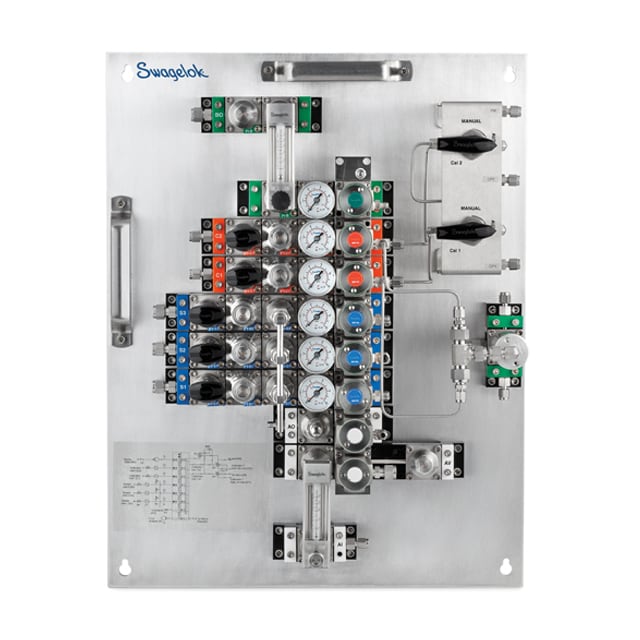

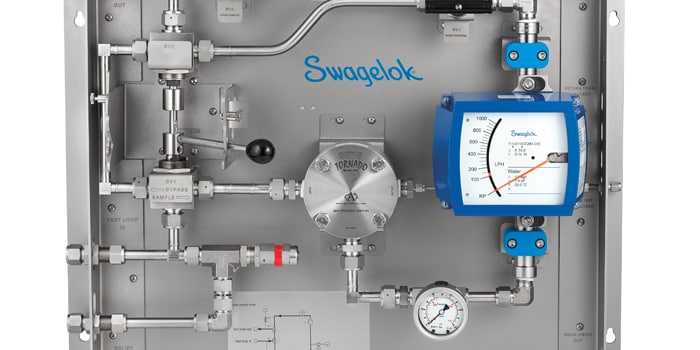

Fast loop modules are designed to handle high flows in sample transport lines to reduce time delays for online analyzer systems. Located at the analyzer shelter and offering a bypass, the Swagelok fast loop module (FLM) can isolate the sample system and introduce a purge gas for system cleaning. The FLM extracts a sample through a filter while using the high flow rate of the bypass to keep the filter element clean.

Get a Faster Response

The distance between a sample tap and an analyzer can make it difficult to obtain a useful analytical measurement. Sample transport lines are commonly more than 100 feet (30 meters) of tubing or pipe and require high purge volumes to ensure a fresh sample reaches the analyzer. Ideally, the flow from the sample tap to the analyzer shelter should take one minute or less. Depending on the tubing or pipe size of the transport lines, as well as the actual transport distance, this flow rate could be as high as 90 std ft3/h (2548 std L/h).

Minimize Sample Waste

A Swagelok FLM also minimizes the amount of extracted sample that is sent to flare or disposal. A bypass filter specially designed for fast loop systems enables the FLM to provide high flow rates. The filter bypasses much of the sample flow and returns it to the process line through a secondary transport line. To generate high flow rates through this bypass loop, the return point must be at a lower pressure than the extraction point. To further reduce sample waste, many Swagelok FLM configurations offer a sample return line from the analyzer (configurations 2, 3, and 4). This option eliminates sending any continuous flow from an online analyzer to flare or disposal.