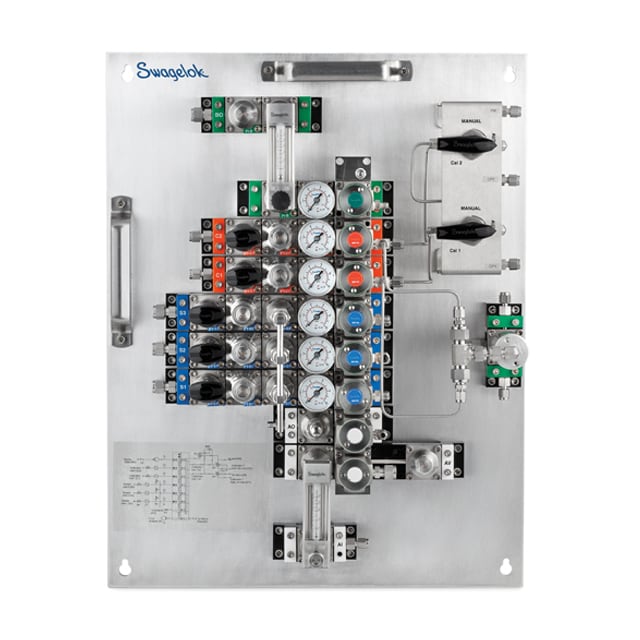

Fluid Distribution Header

Fluid Distribution Header

Why Use a Fluid Distribution Header?

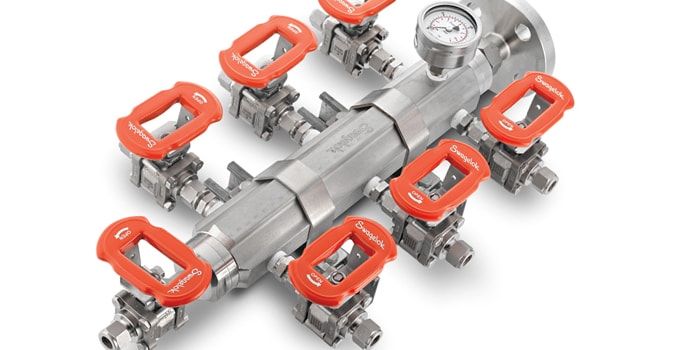

Fluid distribution headers are common components used in a variety of gas and liquid applications. An FDH provides a flow path while allowing multiple outlets, acting much like a large branch fitting.

A fluid distribution header is characterized by an inlet on one end, a drain on the other end, with multiple outlets on the sides. Typical fluid distribution headers are manufactured from a piece of pipe or bar and feature welded or threaded end connections. Using the Fluid Distribution Header as a Distribution Manifold

As a distribution manifold or header, an FDH connects several users to the source of a utility fluid. Typical applications include:

• Cooling water

• Steam

• Compressed air

• Plant nitrogen

In a typical analyzer house, for instance, one FDH is an instrument air header, another FDH is the plant nitrogen header, and yet another FDH is the LP steam header. If needed, multiple FDH subsystems can be screwed together end-to-end to make longer header runs. Typically, an FDH has a main isolation valve and several outlets, each with its own isolation valve. For potentially wet gases, such as compressed air or steam, it is best to install the FDH vertically

with a drain valve at the bottom. For liquid service, it is best to install the FDH vertically, with the supply entering at the bottom

and the top valve acting as a vent for removing trapped air or allowing air in for draining the FDH

during maintenance.