Swagelok Orbital Welding Training

Orbital Welding Training

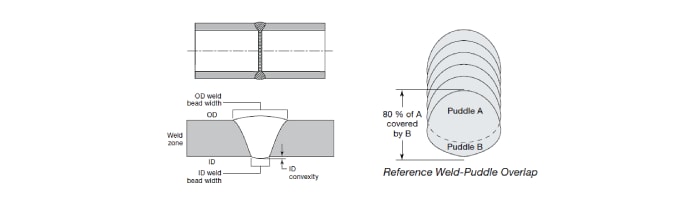

Orbital welding is an automated process in which an electrode is rotated in an orbit around a part joint on a rotor using gears and motors.

Swagelok® M200 welding system, it’s easy to make precise, consistent, quality welds. While automatic orbital welding can help you overcome issues related to widespread welder shortages, proper orbital welding training is essential to equip your emerging welders for success with our five-day orbital welding training course.

Swagelok Orbital Welding Training

For many decades, Swagelok has offered premium-quality welding tools. Today, our welding training emphasizes the theories and skills associated with Gas Tungsten Arc-based orbital Welding (GTAW) with both classroom and hands-on training in a four days course.

Because of the complexity of skills required to consistently achieve good orbital welds, new and experienced welders must be trained using cutting-edge techniques from qualified instructors. The techniques taught in this course can be applied to any automatic gas tungsten arc welding system.

Course Objective:

To gain an understanding of the Swagelok Welding System including weld schedules,

set up and operations to gain high quality orbital weld

What You'll Learn

This course will instruct the entry-level orbital welder and enhance the welding skill knowledge for the experienced orbital welder in the following areas:

download brochure with course outline

Who Should Attend

Course Length 4-5 days*

* On the fifth day you can choose to test for ASME Section IX qualification if you need to fulfill QA/QC requirements.

Your Instructor

All of our instructors hold Certified Weld Inspector (CWI) and Certified Weld Educator (CWE) qualifications, as well as at least five years’ experience in orbital welding instruction.

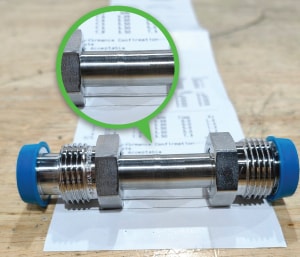

Welding Services by Swagelok Thailand

Swagelok Thailand offers Orbital Welding services and M200 welding machine rentals.

Whether you need precision welding for fluid systems or other critical applications, our expert team is ready to assist you. Contact us today for reliable welding solutions tailored to your needs.

Our Orbital Welding services ensure a high level of consistency, quality, and efficiency. With advanced technology and skilled technicians, we deliver reliable results for industries that demand the highest standards of safety and performance.